Delcam regularly meets with its mint customers and those involved in the coinage industry to ensure that everything from the coin design to the CNC machining/ laser engraving gives a highly accurate and crisp finish to the coin die.

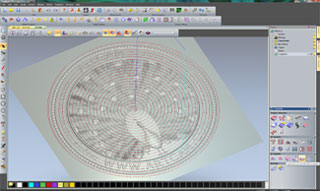

As a result, the spiral machining strategies within the artistic CADCAM software, ArtCAM, were developed specifically for coin manufacturers. The engraver can select this or other toolpaths they wish to run over the coin relief artwork from a choice of CNC cutting tools including any customised tools that they’ve added to ArtCAM’s expandable tool database.

To prevent breakages, multiple toolpaths can be run over the bas-relief, each time running a finer cutting tool over its surface.

To help speed up these toolpath calculations, when used on a 64-bit operating system, ArtCAM utilises its multi-threading technology to dramatically increase the speed at which they are calculated; great when working at high resolution.

These toolpaths, if required, can be reordered at any time and later sent in order to over 300 CNC machines. Alternatively, for laser engraving the designer can use ArtCAM laser engraving machining strategy or simply create an STL file which can be read by their machines own laser software.