Howard Bros. (Engravers) Ltd. is a British company that been in business for over 50 years. To maintain their competitive edge this forward-looking organization has combined traditional engraving skills with state of the art technology. This enables them to supply cost-effective, time driven engraving solutions for a diverse range of industries. Their client list includes international as well as home based companies. Howard Brothers purchased their first seat of ArtCAM in 1996 to run their 2 Kuhlmann CNC engraving machines.

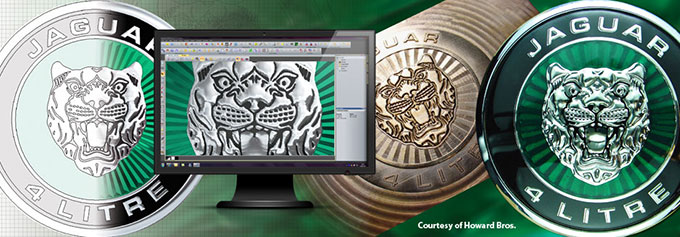

Their first paying job with the software was to design and manufacture a press tooling for 4 Litre Jaguar XK8. The job was particularly complex as the three-dimensional relief needed to be stamped onto pre-printed aluminium, requiring the tool to be produced to a very tight tolerance. The growth and diversity of their business has enabled them to grow and they now have 2 seats of ArtCAM Pro and 5 CNC engraving machines. ArtCAM has allowed them to expand their traditional industry focus and acquire customers in many new and rewarding markets.

These applications include manufacturing plastic injection mould tools, copper and graphite electrodes, coin and medal dies, card embossing tools and many more. The new 3D Model import (STL, 3D DXF and 3D Studio) functionality in release 4.5 has opened up even more opportunities and they are starting to manufacture prototype models and tooling directly from customers CAD models. As ArtCAM functionality grows so do the opportunities for Howard Bros.

Managing Director, John Howard summed up the benefits of using ArtCAM in their production process:

The quality, precision and speed we get from ArtCAM Pro and our flexible CADCAM machining set-up enables us to adopt a business co-operation attitude instead of the usual customer, supplier set up"

For more information on Howard Bros Engravers please visit their website www.howardbros.co.uk