Typically most of the customer work we get to see at the ArtCAM office tends to be of the typical 3-axis low relief nature especially in the woodworking and signmaking industries. However just recently there have been an increasing number of customers’ successfully rotary machining large format pieces, designing them by utilising the unwrap and ring wrap features in ArtCAM. Below you can read about a couple of ArtCAM users who are successfully producing differing types of pieces using this form of machining.

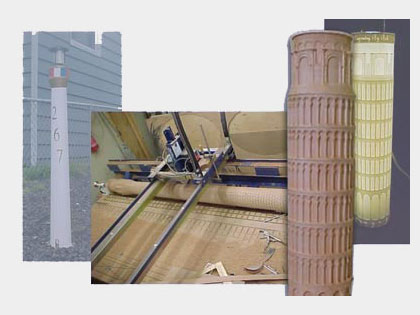

The first of these two innovators is Robert Dodd. I first discovered the work Robert was producing, when by chance he picked up an ArtCAM model of mine from the ArtCAM Forum. The model was of the Leaning tower of Pisa, he promptly emailed me with images showing that he had rotary machined it 3 foot high. This was shown along with a number of other excellent examples including the lighthouse shown below. Robert has been an ArtCAM customer for 2 years but has only been using Pro since December last year, which is a testament to how easy the software is to learn. Robert chose to move to CADCAM, as doing every thing by hand was to time consuming. For his rotary work Robert uses an indexer attachment for his ShopBot machine. This required some level of modification to his machine:

I had to make room to fit this. Firstly I raised the side X rails 5" ,with the C channel steel supports that are spaced, secondly I cut a section out of my spoil board about 8" wide by 8' long, I then installed rails along x axis which are about 10' long ,which lets me use work pieces, from very small to 8' long. I change a value in the control software depending on the dia. of the work piece."

Robert is a frequent poster on the Forum and we shall undoubtedly see more of his terrific rotary work in the future on the showcase area.

Robert Dodd

New Jersey

The second of our customers is Gene Marshall. Gene’s current rotary work is of a more ornamental and architectural nature. It is again a testament to ArtCAM that he has produced this fine array of work after only being an ArtCAM user since the spring of this year. He again uses a ShopBot and indexer. The work shown below which include Corinthian and gothic columns, are just some of Gene’s work. His shop has also made fireplace columns and pedestals. The fact that you can view the wrapped pieces on screen, is also cited, by Gene, as a major benefit when trying to win customer approval.

Four years ago Gene spotted the need in the market for custom ornamentation without to much knowledge of what the power of ArtCAM and CNC could do for his company. Now:

Four years later our addition of ARTCAM has allowed us to offer; Interior and exterior ornamentation, carved, cut or turned, in any specie of wood, with infinite repeatability, and a prompt turn around time……..We love ARTCAM."

Gene Marshall

Both of these guys have shown that with a little bit of inventiveness and ArtCAM Pro your ideas and business can flourish!