Larry Egelhoff, President of Becco Inc. has for the past four years been using ArtCAM Pro to help him produce a variety of small advertising and point of sale products. The small venture was initially started as a hobby, however a number of successful projects have allowed the enterprise to grow.

Larry initially started producing 2D products manually programming the machinery, however the greater interest in being able to produce fully three-dimensional products lead him to purchasing ArtCAM Pro allowing him to confidently take on a wide variety of new projects. Larry has always been impressed with easy-to-use nature of ArtCAM Pro, and its comprehensive post processor support.

I've tried other software and incurred many problems with the transfer of data to the machine. This is not the case with ArtCAM's post processors".

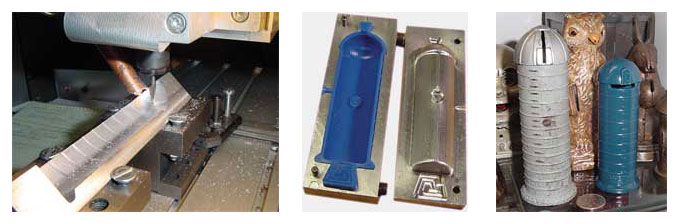

The grain silo toy bank was one of Larry's most recent projects. The job was to design and produce 200 toy banks that were to be given to attendees at a collector's convention. The bank was to be a reproduction of a toy cast iron model of the grain silo that was manufactured in Marietta, Ohio in the early 1900's. The new bank could not be a direct copy but similar for use as a memento of the convention. The quality must meet or exceed the original. Investment casting was the chosen process to achieve the necessary detail.

The bank was to be a two-part design held together with a single screw and would be painted with various colours. As you can see it turned out very well and Larry was pleased enough to share the story with us. Technically the project had a couple of things which needed careful consideration. Using a 3 axis machine, then making the mold in two parts would limit the detail on the sides due to the vertical surface. The answer was to make it a 4-part mold with two parts to be combined for each wax. Screws would hold 2 two parts together. The two mold pieces would need a matching shape for the inside and to determine the wall thickness.

The basic shape was generated as a vector outline. The bands holding the silo together and the steps leading to the top would be a similar outline and utilize the "Merge High" function for a flat step. The cupola at top was made using a similar procedure to the steps. Placing the cursor on the high point and reading the cursor Z information gave Larry the height necessary to extend the cupola beyond the roof edge. The doorframe and hinges were simple add /subtract operations. The text for the base was engraved as a single centerline feature using a 1/32" ball end mill. The inside surface was made as a turned vector.

The material thickness was easily attained using the quick and simple "Offset Vector" command. The coin slot was a simple subtraction from the curved surface and matched the inside surface leaving very little material to be cleaned out later.

The machining was done as 4 separate pieces set at 45deg. Vectors were placed around the area needed by each piece to keep the "air" machining to a minimum. The outside texture was made by using a wide "step over" of the ball mill. Alignment posts and inside features were either hand produced or created as a secondary ArtCAM model, using a copy of the original and deleting unneeded objects and features.

After seeing how successful this project was Larry intends to pursue this market and produce more novelty products in same way. Larry's achievements show how, with ArtCAM's help and with a little imagination even a hobby can lead onto a successful business venture.

Larry Egelhoff

Beeco Inc

(001) 317 547-1717