Home >> Latest ArtCAM News >> Delcam’s ArtCAM Pro makes engraving easy

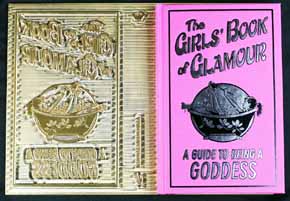

Foiling dies are the engraved plates used to produce the raised text and images on book covers, cards, and boxes for CDs and DVDs. With designs becoming more complex in all these areas, software like Delcam’s ArtCAM Pro is becoming increasingly important in their manufacture. A recent example of the complexity that can be produced easily with the software was the cover produced by Clays Ltd. for independent publisher Michael O’Mara’s Girl’s Book of Glamour using foiling dies from Coatings Direct.

Clays has been working successfully with Coatings Direct, which is based in Harleston, Suffolk, for the past six years. With the use of ArtCAM Pro, Coatings Direct has consistently been able to create blocks from designs supplied by Clays to the high levels of quality, and within the strict time constraints, demanded in the publishing industry.

Vic Britton, manager of the block-making department at Coatings Direct, has been using ArtCAM Pro for almost eight years. Once artwork is received from the manufacturer, a metal plate reproducing the image supplied by the client must be made quickly and accurately as "our industry is extremely time-sensitive, with us receiving deadlines by the hour”. Increasingly complex covers add to this challenge, as the more intricate designs require more plates to be made within the same time frame.

The Girl’s Book of Glamour is an example of a highly complex job for both block-making and production of finished copies, because the cover-for-case design is foiled in two passes; black and silver. This requires two separate plates to be made and an accurate blocking technique when manufacturing the cases. Before ArtCAM Pro was introduced, this would have entailed acid etching to clear away the bulk of the material followed by hand carving the remainder of the design for each individual template. Now with ArtCAM Pro, "for one template, what originally could take up to eight hours to carve now only takes three hours in total,” claimed Mr. Britton.

"Prior to ArtCAM Pro, we were also often faced with inconsistency between plates which meant that we had to adjust them or create the plates again from scratch. ArtCAM Pro however enables consistency and quality,” he added.

ArtCAM Pro can import a variety of file formats such as Photoshop and pdf files sent directly from the customer. Vectors can be created on the image and then be tidied up using a range of the software’s tools to create neat crisp edges. "Vectorizing saves us vast amounts of time as we can clean up the designs before machining,” explained Mr. Britton. "This gives a higher-quality plate that needs less time for refining and re-machining.”

Within the software, specific CNC machining strategies can be selected to match the various machines in the factory, so reducing material wastage and minimising machining times. This time saving could then be passed onto Clays, allowing the finished book to be produced on time.