Home >> Latest ArtCAM News >> Delcam offers 3D woodworking software for 125 Euros at Ligna

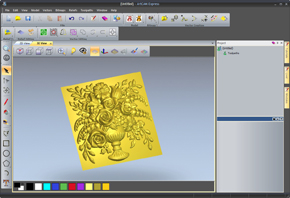

Delcam will show the 125-Euro version of its ArtCAM CADCAM software for woodworking at the Ligna exhibition to be held in Hannover from 30th May to 3rd June. The ArtCAM Express software is believed to be the easiest to learn and the fastest to use 3D woodworking software currently available. Woodworking companies that won’t attend the exhibition can get full details on ArtCAM Express and download a trial version from www.artcamexpress.com.

ArtCAM Express offers 2D drawing, and 2D and standard 3D machining functions, and so provides an ideal introduction to computer-based manufacturing for companies in the woodworking and signmaking industries. A range of modules are available to add extra functionality as the user develops his skills and wishes to take on more complex projects. The software is available in 32-bit and 64-bit versions so that users with the more powerful hardware can work with larger, memory-intensive files.

To suit individual methods of working, ArtCAM gives users the freedom to customise and save their preferred interface layout. This enables every user to set up the software to give quicker access to the commands that they use most frequently. Similarly, commands that are rarely used can be hidden from the initial menu choices.

The software comes with a library of clip-art that new customers can use to create their first models. All these examples can be scaled or combined to give initial designs ready for machining. In addition, designs can be imported in DXF, DWG, AI and EPS 2D formats, plus designs from Alias Wavefront, 3D Studio and other members of the ArtCAM family.

For users that prefer to create their own designs, the software includes a range of drawing tools for creating both geometric and free-form shapes, and also for editing and repairing imported 2D files. The options for text creation support a wide range of standard fonts and also give complete control over spacing, kerning, and line and paragraph formatting. Any new designs created can be added to the initial library for future use.

To help visualise the design, it can be rendered in numerous materials, including all the most common types of wood, such as mahogany or maple, complete with wood-grain direction. If the final design requires external approval from the client, it can be emailed as a rotatable 3D PDF.

Once the design has been finalised, the software offers a variety of strategies for CNC machining. 2D strategies supported include area clearance, profiling, engraving, vector-based machining and drilling, plus V-bit carving on all standard Windows fonts. In addition, a 3D raster toolpath can be created within a vector boundary. The software is supplied with a tooling database, which can be edited or added to by the user.

A simulation can be run of the pieces being machined using the chosen tools and the given material block dimensions. Users can compare the results obtained with different tools or machining strategies on the computer, potentially saving time and money.

The optimum toolpaths can then be exported to more than 250 different types of routing and engraving machines, using Delcam’s proven range of post-processors.

Ten optional modules are available so that users can upgrade their capabilities to match their specific needs as their skills and requirements increase. Three options can be added to give extra design functionality and six to increase the machining options, with the tenth module allowing the import of data from a range of high-end CAD formats, including IGES and STEP.