Home >> Latest ArtCAM News >> ArtCAM: The Innovative Design & Manufacturing Software for Artisans

With international trade levels soaring there is an even greater pressure on jewellers to meet customers’ growing expectations for quality, detail and intricacy of pieces, whilst competing against overseas companies with cheaper labour, metals and manufacturing costs.

Consequently, jewellers are often confronted with the decision to move over to computer-aided design and computer-aided manufacture (CADCAM), or to preserve the tradition and skills of handmade jewellery.

A common misjudgement when making this decision, however, is that turning to a software solution will replace or deskill workers, or result in losing individuality and creativity. With ArtCAM JewelSmith, a CADCAM software solution from Delcam (www.artcamjewelsmith.com), this is not the case as businesses can work in a way that suits them whilst benefiting from faster and cheaper production methods.

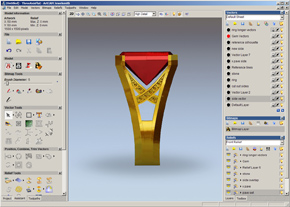

Designed specifically for artisans, ArtCAM JewelSmith enables jewellers to design and manufacture highly intricate personalised or custom jewellery or new complete lines with ease. Whether master model makers prefer to first sketch their ideas on paper, hand sculpt a 3D model or create the piece in a familiar CAD package this can simply be scanned or imported directly into the software. Alternatively designs can be created directly into ArtCAM JewelSmith itself.

To create designs made up of different reliefs (for example a combination of a 3D shape, a texture and some lettering) the jeweller can create and edit designs as a series of layers rather than always having to work with the complete model.

If Jewellers currently work with un-calibrated gems they can now free up hours of valuable time as they no longer have to painstakingly hand set gems one by one to complete their piece. ArtCAM JewelSmith simply takes the dimensions of the gems and creates caps to securely hold them in place. This gives the jeweller time to focus their knowledge and skill on creating and developing other design ideas.

JewelSmith provides an array of sculpting tools that also enables the user to select the areas they wish to shape, change the thickness of their sculpting tool and the strength applied to the relief as well as undo any mistakes or unwanted changes. For hand engravers, ArtCAM can replicate their current working methods by utilizing a Wacom tablet. This way the more pressure applied by the pen to the tablet the more material is taken away.

For ease, the master model maker can render a 3D image of the jewellery model at any phase of the design process to see how their piece will look and make any necessary modifications without incurring additional production costs. This is particularly useful for companies offering a bureau service as these renders can be shown to gain customer approval.

Additionally, if a piece of jewellery is made with more than one material, ArtCAM JewelSmith can display the piece in its entirety and then divide up the piece into separate files for manufacturing. Whether your business chooses to manufacture pieces through rapid prototyping or with CNC machining, ArtCAM JewelSmith’s integrated machining wizards will set the machine toolpaths or provide the necessary output files.

Michael Buckley from Michael’s Designs, an ArtCAM customer, believes that "…we are very strict on quality, so producing first class models is very time-consuming and human hands can only do so much…had I not seen ArtCAM and bought it, I wouldn't be able to compete in today’s marketplace.”

Edward Powell, ArtCAM Development Manager, said that "We are continually developing and improving our product through regular contact with our customers and by our in-house jewellery bureau service using the product on a daily basis. By understanding the jewellery industry and the background of our customers we have also been able to tailor unique training and support services to meet a variety of jewellers’ needs.”